Ensuring Quality in the Plastic Mold Manufacturing Process:

Key Steps in New Part Qualification

In the plastic mold manufacturing industry, ensuring the quality of new parts is essential. This process involves thorough testing, verification, and approval to guarantee that the final product meets all customer specifications, performance standards, and regulatory requirements. This article explores the key steps in the qualification phase of new plastic parts, highlighting how manufacturers uphold quality throughout this critical stage.

Introduction

The Importance of New Part Qualification

The qualification process for new plastic parts is a detailed, multi-step procedure aimed at ensuring that each part functions as intended during mass production. From 3D modeling and prototyping to the final stages of injection molding, each step plays a crucial role in ensuring the product meets both engineering and customer requirements. Depending on the part’s complexity and the customer’s specifications, this process includes several methods, some of which are mandatory.

Key Steps in the New Part Qualification Process

For any engineering project, countless hours go into 3D modeling, prototyping, and refining the design, and the final step is to prepare your designs for the injection mold manufacturing process.

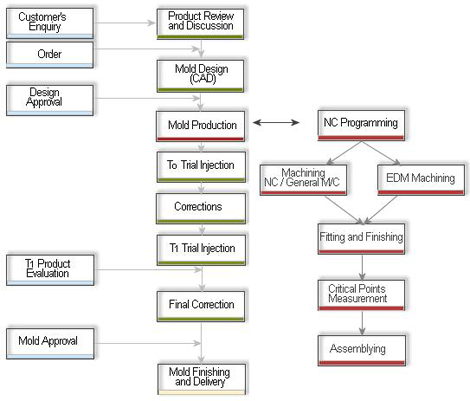

The new part qualification process typically involves the following stages:

Pilot Samples Inspection

The qualification process for a new part involves various methods tailored to meet customer requirements, engineering complexity, and quality constraints. The intensity of the qualification process may vary accordingly. Some or all of the following methods are commonly employed during the qualification phase:

The T1 stage, initial sample inspection, process capability study, pre-production runs for limited sample production, production part approval process (PPAP), ECN release to production after customer approval, and production monitoring and verification are conducted to ensure compliance with all required specifications throughout the production cycle of plastic injection components and assemblies. These verification and inspection processes typically encompass dimensional, functional, and/or destructive tests.

Measurement & Testing

Ensuring Precision at Every Step

A comprehensive inspection and testing procedure supports the qualification process, guaranteeing that every part meets the required specifications. We equip our state-of-the-art inspection lab with advanced measurement tools to achieve the highest levels of precision and accuracy. Some of the key instruments used include

- Coordinate Measuring Machine (CMM): We utilize this precision instrument to inspect and verify the dimensions of parts, ensuring they meet the required tolerances. The CMM assesses every dimension, including the slide, insert, and other key features. Whenever inserts, slides, or any other components undergo heat treatment, it is crucial to recheck their dimensions afterwards, as each stage of processing can impact their accuracy. The Quadra-Check 3D software enhances the CMM’s capabilities, providing advanced measurement and analysis features.

- OGP Optical Comparator: Employed to inspect surface profiles and detect even the most minor deviations in part geometry, this device helps ensure that each part meets the required surface quality standards.

- Standard Measuring Tools: In addition to advanced equipment, we also utilize traditional measuring devices such as calipers, micrometers, thread gauges, and height gauges for day-to-day inspections.

Combined with our expert team, these tools ensure all parts undergo rigorous testing and verification, enabling us to deliver consistent, high-quality results.

Monitoring the Quality System: Continuous Improvement

Once the parts pass initial testing and receive production approval, quality assurance continues. To maintain consistently high standards, our quality system undergoes continuous monitoring. We employ key techniques to monitor and improve quality.

- Internal Audits: The quality system undergoes regular audits to ensure adherence to all processes and prompt resolution of any deviations.

- Corrective and Preventive Actions (CAPA): We track trends in corrective and preventive action requests to identify areas for enhancement in the manufacturing process.

- Product Conformity Analysis: By analyzing product conformity data and quality performance trends, we constantly identify opportunities to improve product quality.

- Customer Satisfaction Surveys: Regular surveys help us measure customer satisfaction, providing valuable feedback that drives ongoing enhancements.

In addition to these monitoring methods, we comply with international quality standards such as ISO 9001, ensuring that all aspects of our production process are continuously optimized for quality and efficiency.

Ensuring Consistent Quality Throughout the Manufacturing Process

The new part qualification process is essential for ensuring that plastic parts meet all customer requirements and perform reliably in their intended applications. Through thorough inspections, testing, and ongoing monitoring, manufacturers can provide parts that conform to the highest quality standards. At DSW, we leverage the latest technology and industry best practices to guarantee the accuracy, efficiency, and quality of our output. If you’re looking for a trusted partner for your plastic mold manufacturing needs, please feel free to reach out to us. We dedicate our team to delivering dependable, high-quality parts with the precision your projects demand.

No comment