Ensuring Quality in New Part Qualification

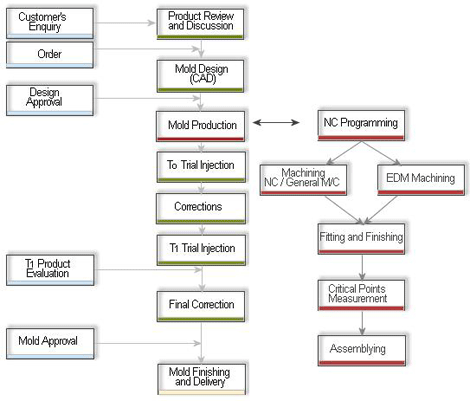

For any engineering project, countless hours go into 3D modelling, prototyping, and refining the design, and the final step is to prepare your designs for the injection mould manufacturing process.

Pilot Samples Inspection

The qualification process for a new part involves various methods that are tailored to meet customer requirements, engineering complexity, and quality constraints. The intensity of the qualification process may vary accordingly. Some or all of the following methods are commonly employed during the qualification phase:

The T1 stage, initial sample inspection, process capability study, pre-production runs for limited sample production, production part approval process (PPAP), ECN release to production after customer approval, and production monitoring and verification are conducted to ensure compliance with all required specifications throughout the production cycle of plastic injected molded components and assemblies. These verification and inspection processes typically encompass dimensional, functional, and/or destructive tests.

Measurement & Testing

Our Inspection Lab ( 3rd party)features state-of-the-art equipment to ensure compliance with the most demanding part and assembly specifications and tolerances:

Microval Coordinate Measuring Machine (CMM) is a precision measuring instrument for dimensionally inspecting and verifying parts.

It is equipped with the Quadra-Check 3D software, which enhances the CMM’s capabilities by providing advanced measurement and analysis features.

OGP Optical Comparator with Smart Edge Detection

Additional standard measuring/testing devices include callipers, micrometres, thread and height gages, and surface plates.

Monitoring of the Quality System

In order to ensure compliance and facilitate continual improvement, our quality assurance system undergoes continuous monitoring through a range of techniques that are selected based on the specific process and its level of importance.

These include:

Conducting internal audits of the quality system

Monitoring trends in corrective and preventive action requests

Analyzing product conformity and other quality performance data and trends

Measuring and monitoring customer satisfaction through periodic surveys

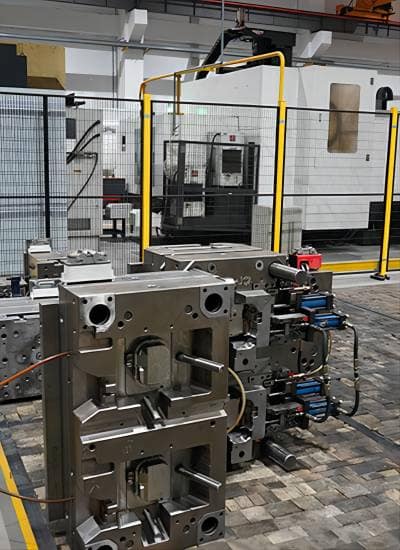

No comment