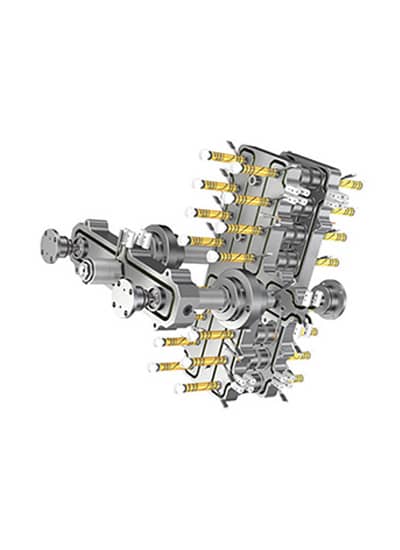

hot runner injection mold

An effective process typically starts by milling or turning mold-forming material, followed by heat treating (in the case of hardened steel), grinding, refined shaping, and finishing treatments like polishing. Once all components have been assembled, care must be taken to ensure it will deliver its intended effects on workpieces.

Hot Runner Injection mold Advantages

Although there will be an ongoing need for cold runner molds, the advantages of using hot runner injection mold systems are so great that they will increasingly be the runner technology of choice for molds used in molding thermoplastics.

The key advantages are:

Reduced Material Waste

Hot runner systems render the need for a cold runner obsolete. A cold runner is a conduit that transports molten plastic material to the mold cavities. In a hot runner system, the plastic material remains molten within the hot runner manifold, thereby minimizing or even eliminating the creation of waste material. This results in substantial material savings and a reduction in production costs. As materials grow more sophisticated and costly, the cold runner consequently becomes expensive waste. The possibility of reusing the runner is uncertain, and in numerous medical and food applications, it is not an option. The process of regrinding and storing the runners incurs significant costs and creates noise and dust. In high-speed, high-cavitation molding operations, the scrap and regrind would pose enormous challenges. However, these regrind issues and their associated costs are non-existent when using hot runners.

Short Cycle Time/ Cost Reduction

In most cases, the cold runner weighs up to half of the total shot weight and typically possesses a section much thicker than the molded part wall thickness. The elimination of the cold runner reduces the cycle time, as the cooling time is controlled by the thickest section. Additionally, the injection screw recovery and injection times experience further cycle time savings due to the smaller shot size.

Molding Efficiency

Hot runner molds offer the advantage of easier startup compared to cold runner molds. This is due to the absence of solidified runners that need to be removed after each under-filled shot before achieving a full mold shot and enabling automatic cycling. The mold is ready for operation with hot runner systems once it reaches the operating temperature. Furthermore, hot runner systems generally allow for lower injection pressures, resulting in reduced mold and platen deflection, as well as minimal flash caused by mold component movement.

Optimal Part Quality

Eliminating the cold runner improves filling and packing conditions by preventing heat loss and pressure drops. Hot runner systems maintain a balanced melt flow, ensuring complete cavity filling and packing. This allows molders to leverage accurate and interchangeable cavities for precise plastic part dimensions. If a cavity is damaged or out of specification, reducing heat to the hot runner nozzle easily prevents the production of faulty parts.

Automating

A growing number of companies are adopting automation of plastics molding and assembly, leading to a rising demand for highly accurate and flash-free plastic parts. When utilized with automation, hot runner molds offer a clear advantage. In addition to ensuring dimensional consistency of the parts, hot runner molds do not have runners present that could become entangled in the mold mechanisms, robots, conveyors, assembly machinery, and other automated systems.

Design Flexibility

One significant advantage of hot runners, often overlooked, is their capability to position the gate at various points on the part. By utilizing hot tip gating, valve gating, or edge gating, hot runner systems enable the gate to be situated at the most advantageous location for optimal filling and/or enhanced part aesthetics. This flexibility provided by hot runners extends to both the part design and the mold itself. The ability to choose the gate location offers flexibility in optimizing cavity orientation, cooling, and simplification of the mold.