ABOUT US

DSW Plastic & Mould

Established in 1998, DSW Plastic & Mould specializes in making plastic injection mold, micro moulding, aluminum die casting, and progressive dies for overseas customers with narrow tolerance and high quality.

As one of the leading plastic mold manufacturers, our focus is on helping you in developing plastic mold with on-time service in the specification.

As a mold manufacturer, DSW promotes a passionate management mode, makes knowledge workers rich in creation and inspiration, and provides knowledge workers with sufficient capability and platform.

- Quality

- Accuracy

- Safety

- Reliance

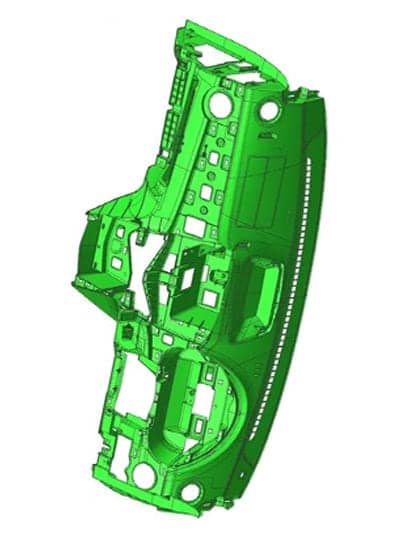

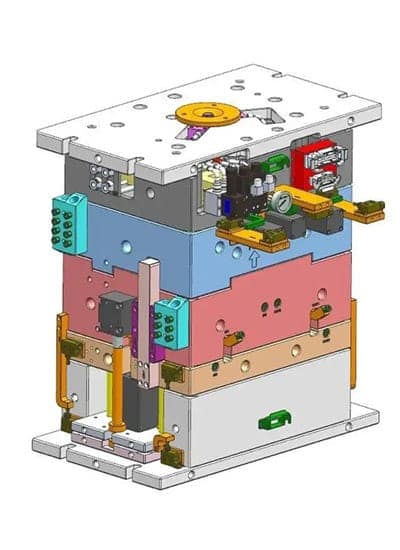

OUR PROJECTS

WHAT WE DONE?

Timeless Products With A Fine Regard For Detail.

ABOUT US

MISSION & VISIONS

We are committed to providing exceptional moulds & services that meet and exceed our client’s expectations.

By leveraging our advanced technology and skilled workforce, DSW strives to contribute to our customer’s success by providing them with cost-effective and efficient plastic molding solutions.

- ConstructionExpert & modern systems

- EnvironmentalWaste management

- MachineryEquipment relocation

- Electrical ServiceElectrical supply stores

WHAT THEY SAY?

TESTIMONIALS

I just made a public announcement here at the office that if there was such a award for Vendor of the Year, you would receive it. We would all vote for you. Very demanding HUGE customer, and you have just went above and beyond!

Jack CarterTechnology Systems

I wanted to thank you and your crew for getting this turned so quickly! Much appreciated and this is why I always choose XTRA for my needs! Well done and this service level is EXACTLY why I choose to use XTRA on my motor!

Nicolas CageIndustrial Inc.

XTRA always has what we need at the right price. Tom is a great help even when it’s something that is hard to find. From the office to Tom or anyone else in back, its always a pleasure to order things that you know will be right the time

John AlabertaIndustrial Factory

RESULTS

We aspire to be on the cutting edge of plastic molding technology, investing continuously in modern equipment and methods.

Our goal is to be a trusted partner to our clients, offering them comprehensive mold design, manufacturing, and support services tailored to their specific needs.

We’re Hiring, Join Our Talent Team

Feel free to contact us and send your resume

Specify the type of material you intend to use for the molded parts. Whether it’s plastic, metal, or another material, detailing its characteristics and properties is vital. Be clear about any special requirements, such as the need for food-grade materials or specific certifications.

Indicate the type of mold you require. Common options include injection molds, die-casting molds, blow molds, and compression molds. Each type is suited to different production methods and materials, so clarity here is crucial.

Specify the number of cavities and cores needed in the mold. This information is essential for determining production capacity and cost.

Estimate the quantity of parts you intend to produce. Suppliers need this information to assess the mold’s durability and plan production schedules.

Define the dimensions of the mold, including length, width, height, and any critical tolerances. Precise measurements are vital to ensure the final parts meet your requirements.

Outline any quality standards or certifications the mold must meet, such as ISO standards, industry-specific requirements, or your internal quality guidelines.

Specify the expected mold lifespan. Different molds have varying lifespans based on material and production volume.

Indicate your preferred delivery timeline. Clear expectations regarding lead times and delivery schedules are crucial to avoid delays in your project.