Plastic Mold Design

Mold design is a crucial aspect of the injection molding process. A well-designed mold ensures the efficient and precise production of high-quality plastic parts.

DSW has been providing custom mold designs for the plastics industry since 2004. We are not a large company, but has many years of experience with plastic mold design and custom molds. We also provide top-tier engineering services to manufacturers in the industry.

At DSW, we have various tooling options available to you, offering different levels of capability from prototype to short pre-production runs to total production quantities.

We can provide you with:

Low volume:-Soft tooling for a few thousand cycles

Medium volume:-P20 (pre-toughened) tooling for up to 20,000

Higher volume:- Fully hardened tooling such as H13 hardened steel in various guises up to 1,000,000 cycles maintenance-free.

Where the cost of several mould tools would be prohibitive, we can offer Family tools that produce more than one component design.

Single Cavity

(low volume/low cost) Multi Cavity

Family Tool (lower tooling cost)

Mold design involves creating a complex assembly of multiple components intended to produce a specific plastic product.

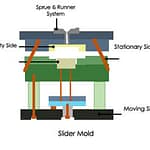

A typical injection mold structure includes key components: mold base for support, cavity and core defining shape, sprue bushing for material entry, runners and gates for material flow, ejector system for product removal, cooling system for solidification, and venting system for air release.

Superior quality: Injection molding produces parts with precise and consistent dimensions.

All are available in Soft or P20 or Fully Hardened tooling

- Total experience in mould design, tool design and manufacture.

- We can tackle the most complex automotive and security components to simple speaker components feet!

- Some customers tap into our expertise for tool design and undertake the manufacture of tooling and plastic components themselves!

Construction Injection Mold Design

1. Standard Molds

The standard molds are simple to construct. They have two sides: the core side and the cavity side. The cavity side flows plastic material between the nozzle and cavity parts.

Standard molds only have one opening and parting direction. This type is used in plastic parts which do not have an undercut or inner and outer screws.

The ejector pin is shown in light brown and straight.

2. Slide mold

This mould has been using slider parts for various types. Basic slide mould transfers horizontal movements of mould to vertical movements. This particular mold variation is particularly useful for producing parts with undercuts, allowing for the creation of intricate geometries and complex features.

3. Three plate molds

Three-plate molds, characterized by two parting lines and a floating plate supported by support pins, offer a versatile solution for gating flexibility. The presence of two parting planes enables the runner system to be positioned on one side of the floating plate or on a dedicated runner plate that attaches to the floating plate. This additional plate, known as the runner plate, allows for enhanced control over the gating location. The utilization of three-plate molds proves advantageous due to their exceptional flexibility, even when employed for multiple cavity configurations.

4. Split Cavity Mold

The split cavity is the same as two two-plate standard molds, but the cavity has a split block to make undercut products or external threads. This type of mold is used when the slider is not enough to make the undercut or the threads. The disadvantage of this mold is when used for little parts, the construction will be complex.

5. Mold With Screw Device

This specialized mold is designed specifically for thread forming applications. It incorporates a rotatable core during the demolding process, allowing for the creation of both internal and external threads. With this mold type, precise and efficient thread formation can be achieved, catering to a wide range of manufacturing needs.

6. Stripper Ejector Mold

This mold type serves the specialized purpose of producing cup-shaped parts without undercuts. Including a stripper ejector facilitates smooth and effortless ejection, ensuring consistent movement and power distribution throughout the product. Moreover, this mold type minimizes the occurrence of unsightly marks on the final product.

Molds with complex and difficult design can be integrated or combined one to the others mold type.

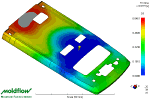

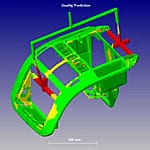

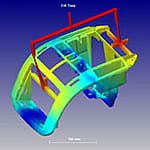

Moldflow Plastic Adviser, Plastics Insight, Moldflow Mpi, Mold Flow Communicator, and Mold Adviser are Mould flow software products for simulating the injection molding of plastic materials. DSW use CAD Connectivity Tools to link structural CAD – CAE to MPI, MPA and MPX Community projects in the plastics and tool-making industry.

After considering the plastic mould design and cost elements, it’s time to mold the plastic. This step is done entirely by the production team. After all, DSW is not only a consulting or injection molding design firm but also a troubleshooter and analysis technician. The moulded plastics production process steps are carefully planned and adhere to industry certification standards. In addition, customers benefit from experienced plastics engineers working on their part. The plastic is cooled and packaged after molding.

These main components work together in a coordinated manner during the injection molding process to produce high-quality plastic products with the desired shape, features, and surface finish.

Plastic injection mold design refers to the process of creating a detailed plan or blueprint for the construction of a mold used in plastic injection molding. It involves designing the mold cavity and core, as well as considering factors such as part geometry, material selection, cooling system design, ejection mechanism, and overall mold structure.

During the mold design process, various considerations are taken into account, including part design requirements, manufacturing feasibility, mold flow analysis, and production volume. The goal is to create a mold design that facilitates efficient and cost-effective production while ensuring the desired quality and functionality of the final plastic parts.

The design of a plastic injection mold involves precise calculations, CAD modeling, and engineering expertise. It requires a thorough understanding of plastic materials, molding processes, mold construction techniques, and industry standards. A well-designed mold plays a crucial role in achieving consistent part quality, minimizing defects, and optimizing production efficiency in plastic injection molding.

No comment