Storage Baskets Plastic

Plastic baskets are versatile storage containers typically used in homes and industries for organisation. They come in various shapes, sizes, and colours to suit different needs.

Plastic baskets come in various materials, such as strong HDPE for heavy-duty options, flexible LDPE for laundry baskets, and balanced PP for heat resistance and some bending.

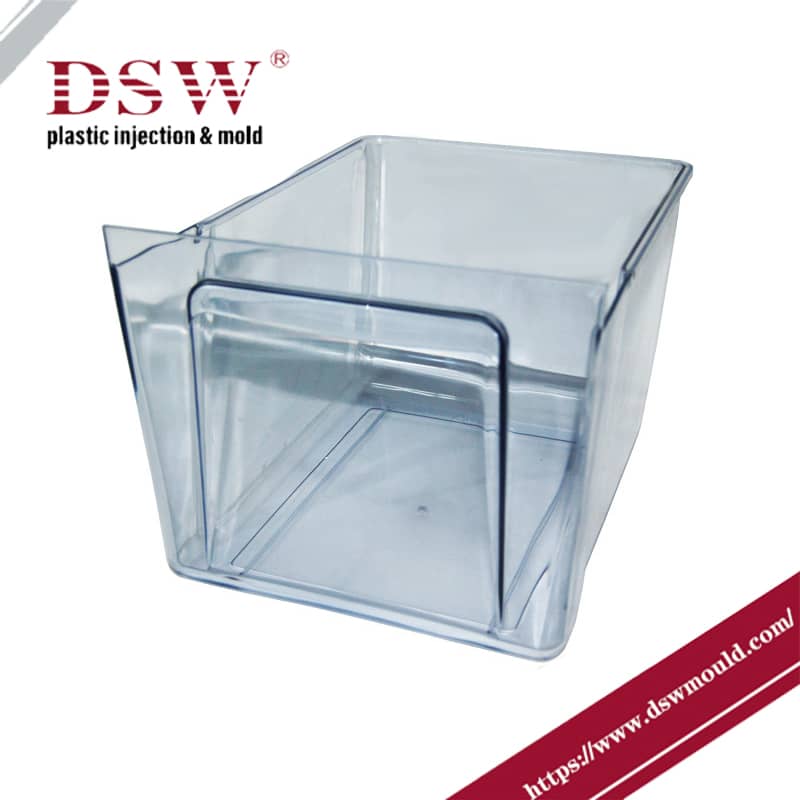

Refrigerator/Freezer Baskets: These baskets are made from a special type of plastic that is safe for cold temperatures. They are ideal for organising and storing food items in refrigerators and freezers.

Sizes: From small baskets perfect for holding office supplies to large ones suitable for storing toys or laundry.

Shapes: Rectangular, square, round, oval, and more, depending on the intended use and desired aesthetics.

Colours: Vibrant colours for kids’ rooms, neutral tones for home organisation, or even transparent options for easy visibility of contents.

Key Features and Benefits

- Durable Construction: Made from high-quality plastic such as HDPE, LDPE, and PP to meet different strength and flexibility needs.

- Multi-Purpose Use: Ideal for organising toys, laundry, books, office supplies, or pantry items.

- Stylish Variety: Available in multiple shapes (rectangular, square, oval), sizes (from compact to oversized), and colours (vibrant, neutral, transparent).

- Specialised Types:

- Laundry Baskets: Large, ventilated designs for dirty clothes.

- Refrigerator Baskets: Cold-safe plastics for food storage.

Behind the Scenes: Plastic Basket Moulds

The key to producing these diverse and functional plastic baskets lies in a process called injection molding. Here’s a glimpse into the world of plastic basket molds:

Mold Design and Engineering: Detailed blueprints are created to define the basket’s shape, size, handle design, and textural features.

Mold Manufacturing: The mold is precisely machined to replicate the intended basket design using high-quality steel or other robust materials. The mold typically consists of two main parts: a core that forms the interior of the basket and a cavity that shapes the exterior.

The Injection moulding process: involves melting plastic pellets and injecting them into the mold cavity under high pressure. The plastic cools and solidifies within the mold, taking the exact shape of the basket design.

Basket Removal and Finishing: Once cooled, the mold opens, and the newly formed plastic basket is ejected. Any minor finishing touches might be applied for a flawless final product.

The Benefits of Plastic Basket Molds for Manufacturers

Mass Production: Injection molding with plastic basket molds enables the efficient production of large quantities of baskets rapidly.

Consistent Quality: The precise nature of the molds ensures consistent quality and dimensional accuracy in every basket produced.

Design Flexibility: Molds can be customized to create baskets with unique features, logos, or branding elements.

Durability and Cost-Effectiveness: High-quality molds can withstand extensive use, making them a cost-effective solution for long-term production.

Mold for Plastic storage basket

Plastic storage basket moulds are used to create these baskets through injection moulding.

Injection moulding involves injecting molten plastic into a hollow mold cavity, replicating the desired basket shape. The plastic cools and hardens inside the mold, forming the final product.

These molds are usually made from P20 or H13 steel for durability. They can be pretty complex, with features like cores, cavities, sliders, and stripper plates to create various basket designs and functionalities.

A Perfect Match: Plastic Storage Baskets and Moulds

Combining innovative plastic basket designs and efficient injection moulding creates a win-win situation for manufacturers and consumers. Manufacturers benefit from efficient production and consistent quality, while consumers enjoy plastic storage baskets’ convenience, affordability, and functionality.