Plastic Mould Quality Control & DFM

Tooling Quality Inspections and documentation.

We offer a variety of mould inspections and validation services to ensure each tool meets exact specifications before it goes into production. These include:

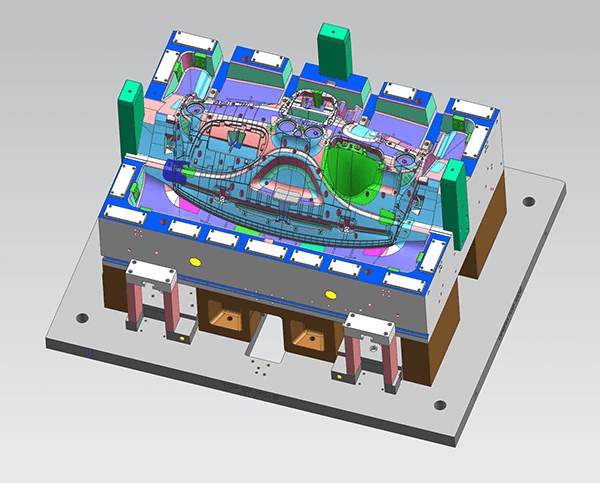

- Mould Design Verification: Comprehensive review of 2D and 3D designs to ensure tooling feasibility and function.

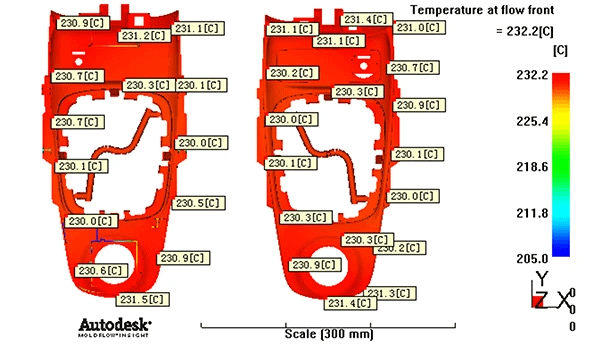

- Mould Flow Simulation Reports: Analysis of plastic flow, pressure, and temperature to predict potential moulding issues.

- Steel Certification: Verification of steel hardness and authenticity for tool durability.

- Trial Reports (T0, T1, etc.): Documentation of test shots and dimensional accuracy.

- Final Cavity/Core Inspections: Precise measurements to validate mould dimensions.

These checks minimise the risk of rework and ensure that each mould is ready for high-volume production.

Design for Manufacturability (DFM) and Mould Design Reviews

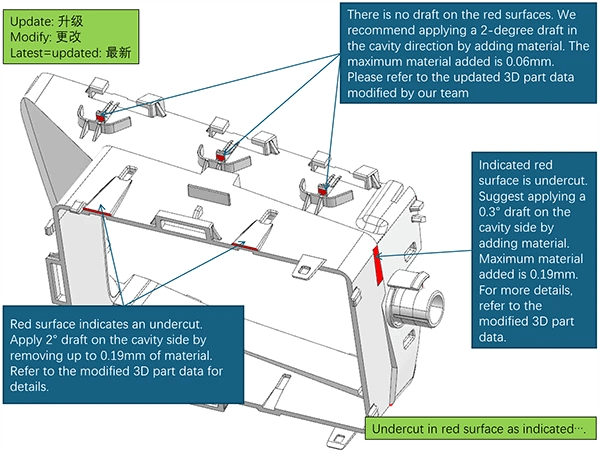

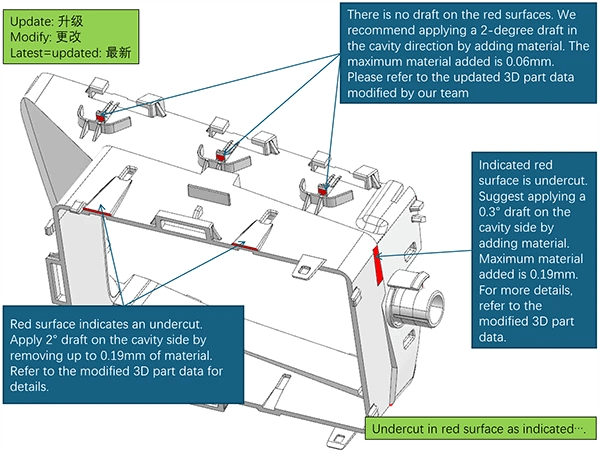

Every quote includes a Design for Manufacturability (DFM) analysis, highlighting opportunities to improve tool life and part quality. Key considerations include:

- Uniform wall thickness reduces warpage.

- Proper draft angles for easy ejection

- Managing undercuts and shutoffs

- Optimised cooling system layout

- Sufficient venting to avoid burn marks

We also perform a detailed tooling feasibility check using CAD software. Our team collaborates with customers to fine-tune their designs for optimal moulding outcomes.

Engineering Support & CAD Revisions

Our experienced toolmakers and engineers use professional software, such as UG/NX, SolidWorks, and Moldflow, to support your project from concept to production.

In cases where improvements are required, we provide:

- Technical Feedback: Highlighting potential design risks or manufacturing difficulties.

- Proposed Revisions: Modified CAD files with tooling functionality, cooling, or maintenance access enhancements.

This hands-on collaboration ensures the mould is engineered for performance and efficiency.

Mould trial, qualification, and process validation

We conduct structured mould trials (T0, T1, T2) to evaluate tool functionality and part performance. During these tests, we monitor:

- Dimensional accuracy of parts,

- Flash, mismatch, or sink marks,

- Filling balance and short shots.

Upon successful trial runs, we process validation to confirm the mould maintains consistent output under production conditions. Once approved, the tool is released for full-scale manufacturing.

Scientific Mould Setup & Repeatability

To ensure that every moulding run meets the same high standards, we document all key mould setup parameters, which include:

- Optimal temperature settings

- Cycle time and pressure

- Gating and cooling system performance

Our scientific mould setup guarantees repeatable results, whether a mould runs immediately or months later. By maintaining consistency across runs, we minimise downtime, scrap rates, and quality issues.

Manufacturing Process Control for Plastic Moulds

At DSW, we base our approach to controlling mould manufacturing on stringent protocols and a commitment to precision engineering. Key control elements include:

- Machining Process Validation: Each machining operation, from rough milling to precision EDM and CNC finishing, is monitored for dimensional accuracy, surface finish, and tool wear.

- In-Process Measurement: Important measurements are checked at different stages of production using high-tech measuring tools, like coordinate measuring machines (CMM), to make sure they match the 3D CAD model.

- Tool Assembly Standards: Rigorous assembly procedures are adhered to to align and fit cavity and core inserts, cooling systems, and ejection components with minimal tolerance variation.

- Process Documentation: Each step, from tool design approval to final mould assembly, is recorded for traceability and quality assurance.

These manufacturing controls are vital for delivering high-performance tools and minimising rework, downtime, and long-term maintenance.

Ongoing Maintenance and Tooling Lifecycle Management

Our commitment to quality doesn’t cease upon delivery. We provide maintenance and lifecycle management services to enhance the lifespan and performance of the mould.

- Preventive maintenance schedules

- We monitor the replacement of wear parts, such as ejector pins and lifters.

- Mould cleaning and inspection protocols

- Storage guidelines and repair history records

This assists customers in safeguarding their investment and ensuring production lines operate smoothly.

Conclusion

Plastic mould quality control is essential for the success of any injection moulding project.

At DSW, we take pride in our systematic tooling design, inspection, and validation approach.

Our integrated quality systems ensure that every mould we deliver is optimised for durability, precision, and efficiency. Partner with us to obtain reliable tooling backed by engineering support and documentation you can trust.