Density of ABS Material

Understanding the density of ABS plastic is crucial for manufacturers and engineers working with plastic injection molding and other thermoplastic processes. In this guide, we explore how the density of ABS material affects its performance, how it compares to other plastics, and the factors that contribute to variations in ABS density. Whether you’re dealing with ABS plastic density in industrial applications or considering it for medical, electronic or consumer products, this article provides the essential information you need.

1. What is the typical density of ABS plastic?

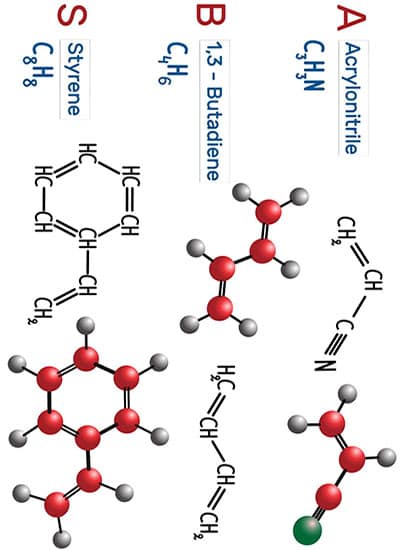

The density of ABS plastic refers to its mass per unit volume, typically measured in grams per cubic centimeter (g/cm³) or kilograms per cubic meter (kg/m³). ABS, or Acrylonitrile Butadiene Styrene, typically has a density between 1.0 and 1.05 g/cm³, translating to approximately 1,050 kg/m³. This places ABS in a moderate range compared to other engineering plastics, such as nylon or polycarbonate, but it is heavier than standard plastics like PVC or polystyrene.

2. How Do You Calculate Plastic Density?

To calculate the density of plastic in g/cm³, the mass of the material is divided by its volume. This measurement is critical for ABS in determining how the material behaves under different conditions, including temperature, pressure, and mechanical stress. A more precise understanding of the ABS material density helps manufacturers predict performance in various applications, from automotive components to electronics.

3. Factors Affecting the Density of ABS

The density of ABS material can vary depending on several factors, including its chemical composition, manufacturing process, and the use of additives. Key factors include:

Base Resin: The specific formulation of ABS resin can affect its density. Different manufacturers may use slightly varying compositions, impacting the final ABS plastic density.

Additives: Reinforcements like glass fibres, flame retardants, or plasticisers can increase or decrease ABS’s density.

Recycled Content: The use of recycled ABS materials can influence the density due to variations in quality and impurities.

4. Processing Efficiency of ABS

The relatively low ABS density contributes to its efficiency in processing, particularly in plastic injection molding. Due to its low viscosity and manageable processing temperatures, ABS is easy to mold into complex shapes. The material’s flow characteristics make it a preferred choice in industries that value efficiency, such as automotive manufacturing.

Furthermore, ABS material density affects cooling times and cycle rates in the molding process. Lower-density ABS tends to cool faster, improving production speed, while higher-density ABS, often reinforced with fillers, requires more precise control to maintain product consistency.

5. Impact of Additives on ABS Density

The addition of fillers or reinforcements can significantly alter the density of ABS plastic. For instance, glass fiber-reinforced ABS has a density ranging from 1.2 to 1.4 g/cm³, which is higher than standard ABS. This increase in density improves the material’s mechanical strength and heat resistance, making it suitable for demanding applications like automotive parts or industrial equipment.

In contrast, lightweight ABS, designed for applications that require weight reduction, might have a density below 1.0 g/cm³ due to the inclusion of foaming agents or other low-density additives.

6. ABS Density and Injection Molding

The density of ABS plays a significant role in plastic injection moulding, influencing

.Flow rates: Lower-density ABS typically flows more easily, making it suitable for complex or thin-walled parts.

Cooling time: Lower-density ABS cools more quickly, speeding up production. Conversely, higher-density ABS may require longer cooling times.

Shrinkage rates: Lower-density ABS can exhibit higher shrinkage, which may lead to dimensional inaccuracies, while higher-density ABS offers better dimensional stability.

The ABS plastic density must be considered when designing molds and selecting the appropriate injection pressure, as variations in density can impact the final product’s quality and performance.

7. Comparing ABS with Other Plastics

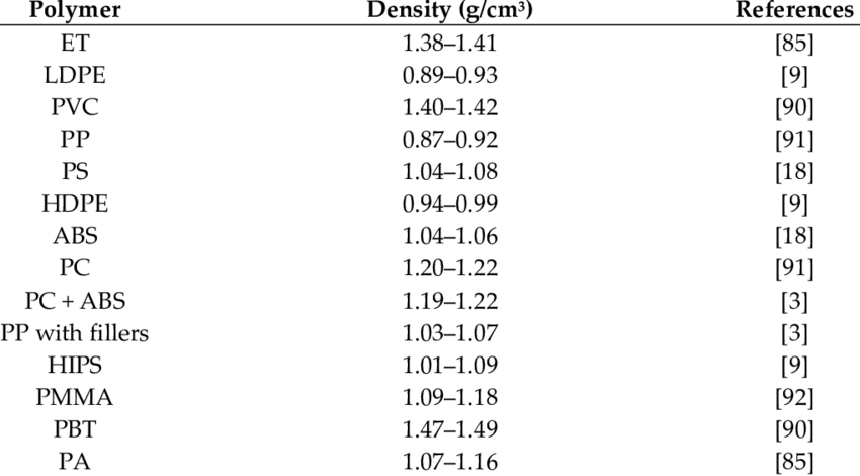

When comparing the density of ABS material to other plastics, ABS tends to be lighter than materials like PC/ABS (Polycarbonate/ABS blends), which have a density of around 1.15-1.22 g/cm³. This difference makes ABS an attractive option for applications where weight savings are essential. However, PC/ABS material density offers improved toughness and heat resistance, making it ideal for more demanding uses.

On the other hand, ABS is lighter than PLA, which typically has a density of 1.24 g/cm³. This slight difference can influence material choice depending on the application’s requirements, such as weight or impact resistance.

8. Examples of Different ABS Densities

The density of ABS plastic can vary between factories based on the processing methods and additives used. For example:

Standard ABS for consumer goods typically has a density of 1.04 g/cm³. Factories producing electronics or household items may focus on impact resistance while keeping the density within the standard range.

Glass fiber-reinforced ABS used in automotive components can have a density of up to 1.4 g/cm³, providing improved mechanical strength and heat resistance.

Flame-retardant ABS, commonly used in electrical components, may have a density between 1.1 and 1.2 g/cm³, with the flame-retardant additives contributing to the increased weight.

Conclusion

The density of ABS plastic is a crucial material property that significantly influences both processing efficiency and the mechanical performance of the finished product. Whether standard ABS is used for everyday consumer items or reinforced grades are employed in industrial settings, understanding how its density interacts with additives, manufacturing methods, and injection moulding parameters is essential for optimising production and ensuring consistent product quality.

By selecting the appropriate ABS formulation with the right density, manufacturers can customise materials to meet specific application requirements—ranging from lightweight automotive parts to robust flame-retardant enclosures. This capability to adjust and control ABS density provides engineers with valuable flexibility, highlighting ABS’s status as one of the most adaptable thermoplastics in the industry.