Plastic Tooling Maker

At DSW, we are dedicated to excellence in mould manufacturing, fostering a culture of innovation, creativity, and inspiration. We empower our team of knowledge-driven professionals with the tools, resources, and opportunities needed to excel.

Trusted Mold Supplier

With extensive experience in the moulding process, DSW handles challenges such as tool flex, twist, and crush during production. This ensures precision and top-quality molds in every order.

16 Years of Expertise

With 16 years of experience, DSW is a trusted mold manufacturer recognized for delivering custom, high-quality mold and die solutions across a wide range of industries, including automotive, lighting, medical, agricultural, and machinery.

Our Mission

As a mold manufacturer, our goal is to deliver superior products, competitive pricing, and exceptional service. We are constantly improving to meet and exceed customer expectations.

We Are Professional?

In plastic molds, plastic injection moulding for various industries.

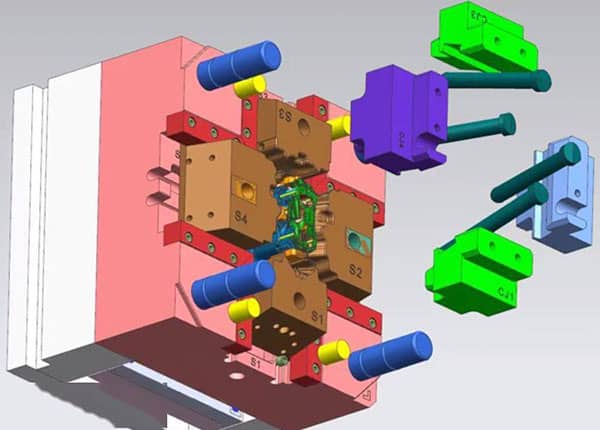

DSW offers our customers a complete set of mold design and tool engineering solutions and has software that analyzes the molding filling process and establishes filling times, cooling times, material shrinkage, flow direction, and molded-in stress.

- UL material approval,TQM system ISO9001:2015

- Corporation system with long standing employees

- Smooth transition from design through to tooling and production

We Are Trusted?

With over 20 years of industry expertise, we are a trusted partner for leading manufacturers worldwide.

The China General Administration of Customs recognizes DSW and has been listed in the “China Export Leading Indicator” survey since 2019. Our experience and reliability back our reputation as a trusted mold manufacturer and supplier.

- Offer a broad range of cost-effective mould solutions.

- Maintain a robust inventory of parts and products.

- Provide repair services to a diverse customer base across multiple sectors.

We Are Expert

Offers flexibility, stability, cost-efficiency, and versatile finishes for industries.

We review the plastic molds for more than just inserts and tight tolerances. Mold filling requirements and runner balancing are considered. The strength of steel is evaluated for steel deflections that may lead to flash or even mold breakage. Understanding the molding process, the molding press, and molding process can generate tool flex, twist, and crush.

- Offer a broad range of cost-effective industrial solutions

- Maintain a robust inventory of parts and products

- Provide repair services to a diverse customer base across multiple sectors