Injection Molding Solutions

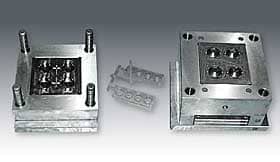

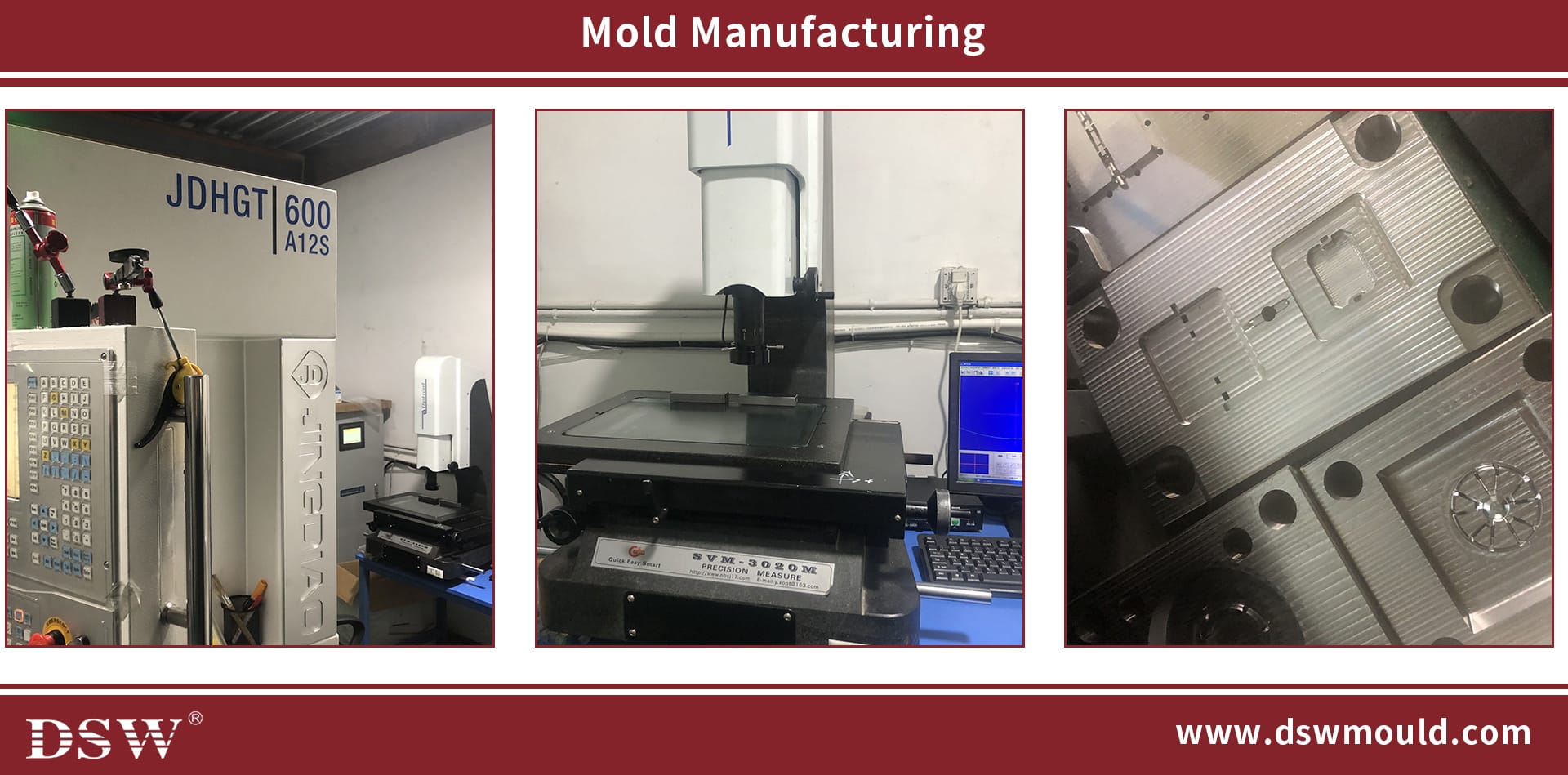

Our experienced die & tooling department personnel use their decades of combined experience in custom mold design to ensure the most precise tooling results.

For plastic injection tooling and prototyping applications, we meet your and your customers’ quality demands.

The PLASTIC INJECTION MOULDING process can be performed with various materials, including metals, glasses, elastomers, confections, and, most commonly, thermoplastic and thermosetting polymers.

Injection moulding is the most common modern method of manufacturing plastic parts; it is ideal for producing high volumes of the same object.

Project Details

| Export to(Country) | USA |

| Tool Description | Plastic Injection Mould |

| Material Type | ABS |

| Cavitation | 1 |

| Weight of Plastic Product | 301g/pcs |

| Mould Design by | DSW |

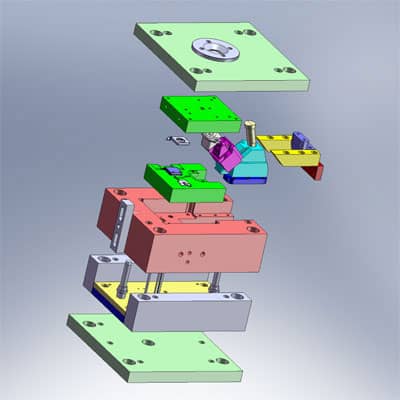

| Mould Construction | Standard |

| Mould Base | LKM |

| Cav.Material | NAK 80 |

| Core Material | 2738 |

| Side Action | Mechanical Slide |

| Ejection | EJ pins |

| Mould Life | 500,000 |

| Moulded Part Inspection By | Moulder |

Features

Complex Part Design: Injection molding can handle highly complex parts, provide uniformity, and make millions of virtually identical parts.

High Efficiency and Fast Production: The injection moulding process is rapid compared to other methods, and the high production output rate makes it even more effective. With the short period between cycles, more injection moulded parts can be produced in a given production time.

Enhanced Strength: Modern lightweight thermoplastics can endure even the harshest environments on par with metal parts and, in some cases, may surpass metal. In addition, more than 25,000 engineered materials can be used for complex injection-molded applications. High-performance plastic blends and hybrids can also be created to meet particular part requirements and characteristics, such as high tensile strength.

Flexibility in Color and Material: The plastic injection moulding process provides flexibility. This flexibility can be in such things as the plastic’s properties or in the ability for OEMs to make custom colour choices to meet specific project requirements.

Partnering for Success

At DSW, we combine our expertise with cutting-edge technology to deliver high-quality, complex plastic parts efficiently and in large volumes.

Whether you’re a seasoned manufacturer or a startup with a novel idea, we can help you bring your vision to life through the power of plastic injection molding.

Contact us today to discuss your project and explore how our injection molding solutions can take your product from concept to reality!