Plastic Injection Molding

Plastic injection molding is a manufacturing method that produces high-volume plastic parts by injecting molten plastic material into a mould cavity.

Founded in 1998, DSW Industry focuses on plastic injection molding as a full-service industry. They offer several services, including plastic injection moulding, mould making, prototyping, OEM services, startups, and secondary operations.

Examples of products We manufacture are automotive plastic, industry machine parts, electronic buttons, electrical closures, boxes, high-tolerance brick toys, plugs, alarm parts and so on.

They serve automotive, security, consumer goods, electronics, medical, and communications industries.

Due to its reliability and flexibility in design options, thermoplastic injection molding is used in many industries, including packaging, consumer & electronics, automotive, medical, and many more.

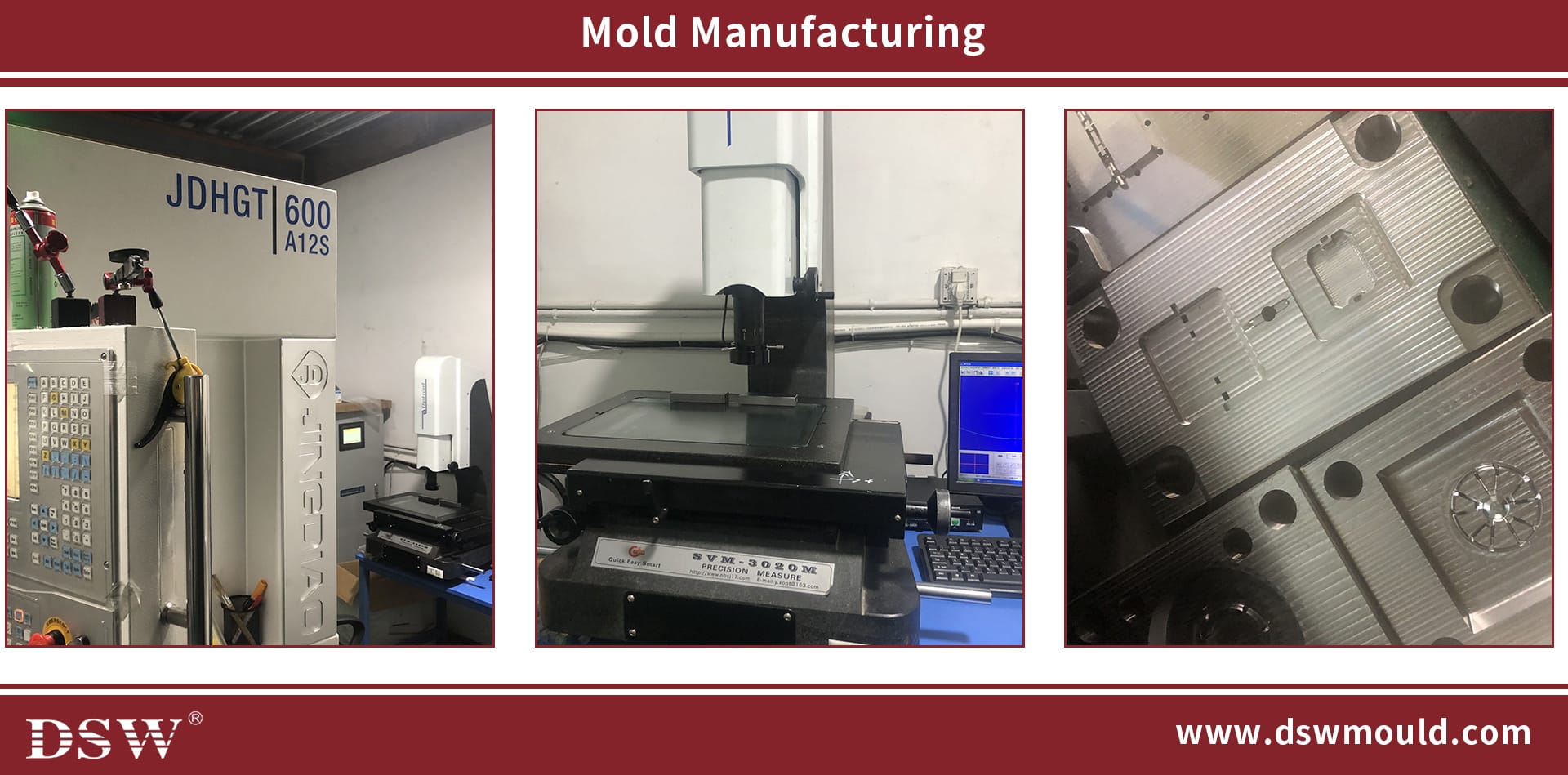

The proficient members of our die and tooling department utilize their profound proficiency in custom plastic injection molding to ensure unparalleled precision in tooling outcomes.

With decades of combined experience, we guarantee precise and accurate tooling results. Moreover, we are dedicated to meeting not only your quality requirements but also those of your esteemed customers regarding plastic injection and prototyping applications.

PLASTIC INJECTION MOULDING

| Export to(Country) | USA |

| Tool Description | Plastic Injection Mould |

| Material Type | ABS |

| Cavitation | 1 |

| Weight of Plastic Product | 301g/pcs |

| Mould Design by | DSW |

| Mould Construction | Standard |

| Mould Base | LKM |

| Cav.Material | NAK 80 |

| Core Material | 2738 |

| Side Action | Mechanical Slide |

| Ejection | EJ pins |

| Mould Life | 500,000 |

| Moulded Part Inspection By | Moulder |

What are the most common types of plastic injection molding processes?

The traditional thermoplastic injection molding process can be modified to include processes that help to enhance part quality and design flexibility.

Below are some examples:

Thermoset injection molding

Molding with thermoset materials requires heat or chemical means to cross-link polymer chains.

Overmolding

Overmolding is an injection molding process where one material is molded on top of another.

Gas-assisted injection molding

At the end of the injection phase of molding, inert gas is introduced at high pressure into the polymer melt.

Co-injection & Bi-injection molding

Injection of two different materials using either the same or different injection locations.

Microcellular injection molding

Use of physical blowing agent, chemical blowing agent (CBA), or mold core-back process to trigger foaming of polymer inside the mold.

Powder injection molding (PIM)

Forming technique for producing small components using powders, typically ceramics (CIM) or metals (MIM), and binding agents

Injection Molding and CNC Services

DSW Molding is a China plastic injection molding company that is proud to go beyond customer expectations.

Experienced and friendly employees

Fast quotes

Rapid lead times

High-quality manufacturing processes